Designs for precision engineering

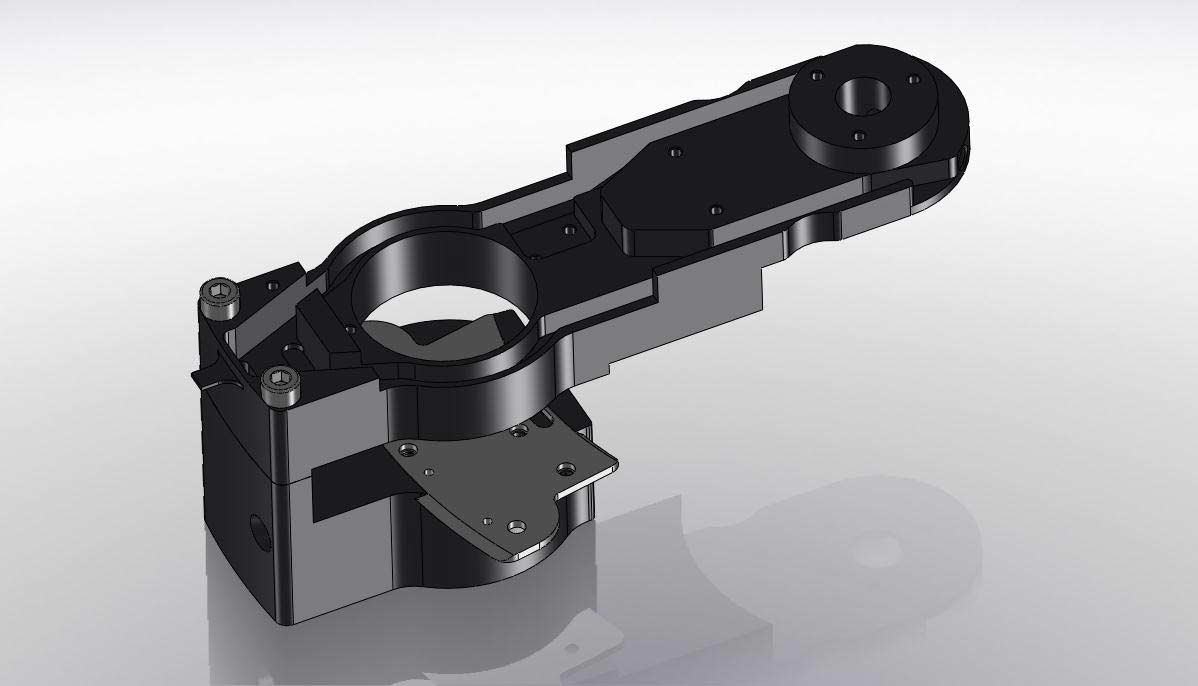

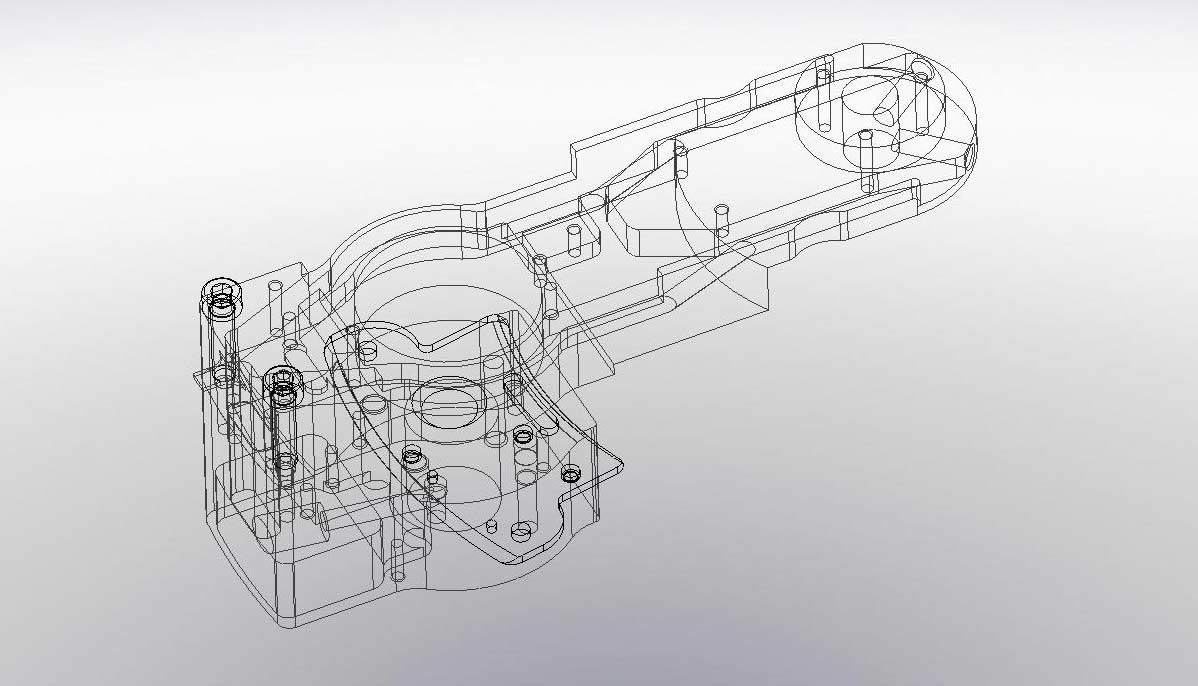

Precision Mechanical Design

Precision mechanical design is a complex process that requires advanced experience and expertise. Our designers use cutting-edge tools such as computer-aided design (CAD) and computer-aided engineering (CAE) to ensure that each component is optimally designed.

Material Selection

Material selection plays a vital role in precision mechanical design, as material properties directly impact the product's performance and longevity. Choosing the right material ensures optimized wear resistance, finish quality, corrosion resistance, and overall reliability, while preventing failures and breakages. Entrusted to our experts, this process guarantees that every component meets the required standards and fully addresses the project's needs.

Key Industries

We excel in producing high-precision components for industries such as medical, pharmaceutical, packaging, defense, scientific research, and aerospace. With cutting-edge techniques and innovative materials, we significantly contribute to the success of our clients.

Why choose us

Our strength lies in our ability to transform clients’ ideas into tangible projects, providing full support from design to production. We use parametric design software that allows us to virtually test every solution, ensuring precision, time savings, and cost optimization.

Every project begins with an in-depth analysis: our professionals tackle and solve even the most complex challenges using modern technologies to achieve flawless results.