The future of industrial production is increasingly robotized, characterized by

intelligent machines that provide

essential support throughout various production processes, simplifying and

easing human labor.

This sector is highly strategic for the country's industrial development: the

robotic revolution intersects with the

Internet of Things (IoT), with its interconnected machines, and

with artificial intelligence,

marking a historic shift that is set to redefine the standards of industrial

robotics.

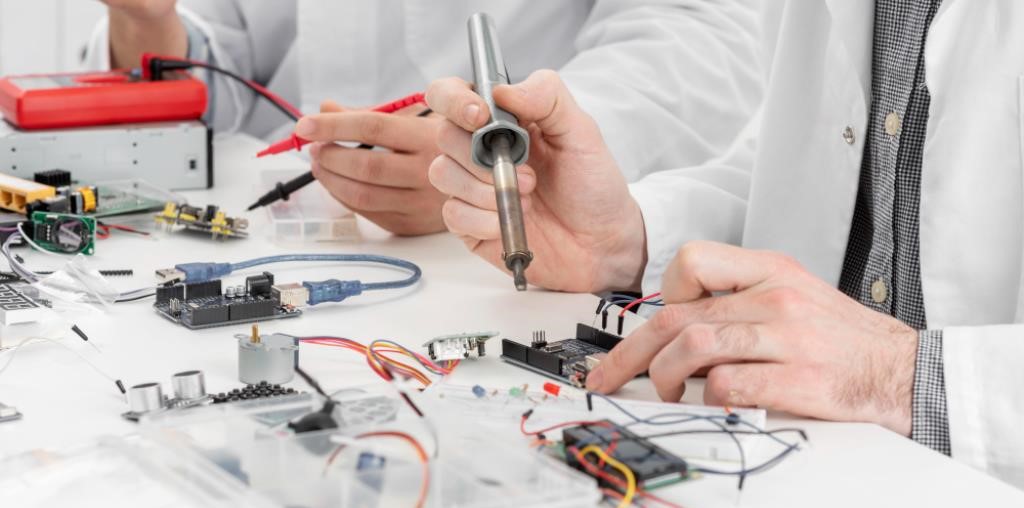

Precision Mechanics in the Construction of Robots

The creation of such advanced and high-performance machines requires an extremely

high-quality standard, involving

every single component, even the smallest or seemingly insignificant ones. It is

in the details that the difference

lies—a core principle of precision mechanics.

This excellence allows the production of technologically cutting-edge tools,

capable of supporting and optimizing

various production flows.

The increasing integration of digital technologies in mechanical processing,

alongside complex automatic systems,

has led to a significant boost in production quality, minimizing the

margin of error in the creation and

supply of small parts for robotics. Precision mechanics enables the

manufacturing of highly specialized

components for the application of robots in any production sector.

The process begins with the reception of the customer’s project, in the form of

a basic drawing, which is then

processed using CAD software for assisted manufacturing. This allows the

identification of the necessary mechanical

operations based on the specific geometry of the component.

The Evolution of the Assembly Line: Tasks and Benefits

Robotics is applied in numerous industrial sectors. The integration of robots

into the assembly line enables a

significant reduction in processing times and a substantial improvement

in the quality of the final

product.

The use of automation and robotics is a cornerstone of the hi-tech future,

transforming industrial environments into

spaces dominated by robots and automated peripherals. The benefits offered by

robots are unmatched in terms of speed

and precision, but the role of the human operator remains indispensable. The

experience and know-how of the

technical staff are essential to ensure proper maintenance and accurate data

interpretation.

Industrial robots, often of the anthropomorphic type, are

composed of joints and

articulations (which determine movement) and rigid bodies. Each

component defines the robot’s

operational capabilities. Even material-handling systems are made up of

mechanical elements designed to enable the

robot to perform its tasks. Every stage, from design to assembly, requires

components custom-made by specialized

companies.